Die Cutting

See the counters we have on offer in our Die Cut Counter Showroom

My 60th Birthday present from Sally is an Ellison press to get me started on that extension to our hobby that is 'DIY Die-Cut Counters'.

This is one of those things that you have to jump into with both feet, as there isn't really a low-cost means of entry. The die-press costs almost £250 (and that is a good price) and the dies, which have to be custom made, are themselves well over £100 each. Even the tins of spray glue are expensive.

The good news is that there is a small but very helpful community of fellow enthusiasts out there to support anyone interested in taking this up. And, though I'm only just starting my own journey, I'm creating this page and its resources as my contribution to the cause.

Here you will find:

- Links to tools & equipment (including the press)

- Links to templates

- Links to counter icons

- Tutorial videos

- Hints & tips

- and eventually more besides.

TUTORIAL VIDEOS

I am in the process of recording and posting a number of tutorial videos on YouTube. The intention is to keep each of these short (ideally under 10 minutes) and to deal with a single part of the production process in each.

TOOLS

There are some basic tools that you will need from the off:

Die Press (and associated accessories e.g. cutting board) (Target Price c. £230)

This will probably be your single biggest investment. The tool of choice (and the one I have) appears to be the Ellison Prestige Pro. Be sure to shop around as prices vary significantly and shipping may will be a key consideration as this baby weighs over 50lbs. I got mine of Amazon UK at a really good price and with free (Prime) shipping.

Dies (Target price c. £125)

Another hefty investment will be the dies. These need to be custom made. Ellison have made dies based on the 1/2" and 5/8" templates you'll find on this page - so that should be able to duplicate those for you. However, my understanding is that they are expensive at around $250 plus shipping, and I've found them totally unresponsive to my emails.

I have found a UK die maker, Atlas Dies Ltd., that has made the 1/2" die for me for £126 (inc vat and shipping). Atlas have been very responsive and helpful and I received the die within a week of ordering it.

Important: The dies will need retractable alignment pins in the two positions shown on the template. I specified 1/8"/3mm diameter.

Die Templates (Target Price: £0)

The templates are used in two ways:

1. Fort he manufacture of the dies

2. For the creation of the counter graphics

The graphics need to align perfectly with the die and so the same template should be used for both purposes. Either send your template to the manufacturer, or get them to provide you with a copy of the template they have used. Because Atlas Dies had not made this form of die before, I supplied the template.

The template I used is the 1/2" one below. I'm planning to have a 5/8" die made too and will use the second template below. I'm also anticipating having a 1/2" x 1" die made - if I do I'll adapt the 1/2" template and send that to Atlas. However, in the unlikely case that I have a die made for circular counters, I'll be getting them to provide the template (which they have said they can do), as I have no idea how to lay that out.

The templates linked here have been produced by John Cooper and have been adopted by all of the DIY die cutters I know of. John has kindly made these freely available.

Adhesive

Personally I no longer use adhesive, having adopted A4/Letter adehesive labels for the counters instead. Many of the DIY die cutters I know doo use spray adhesive however. I've moved away primarily due to the fact it is toxic and gets everywhere.

I've had two types of adhesive recommended to me:

- 3M SprayMount Permanent Spray Adhesive (Target Price c. £13)

This allows you to maneuver the counters slightly on the board for a short period after application. - 3M 7000116782 Super 77 Multi-Purpose Spray Adhesive (Target Price c. £16)

This is a stronger glue than the SprayMount and may therefore give superior adhesion.

WARNING

Ensure you are in a well ventilated area when applying spray adhesive, and wearing an appropriate mask is recommended.

PPE Face Mask (Target Price £20)

A couple of people have commented, on seeing my videos, just how hazardous spray adhesive is. As a result I have moved away from a simple dust mask and now use a filtered mask. I'd suggest you do the same - they are not overly expensive. Of course, if you use self-adhesive labels instead, ther eis no need for the mask.

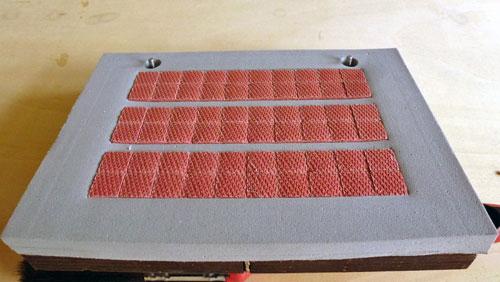

Flower-Press (Target Price £15)

If you're using spray-adhesive (as opposed to self-adhesive labels), once you have applied your counters to the card, it is a good idea to apply weight to improve adhesion. This can be as simple as a few heavy books. I've chosen to take it one stage further and use a flower-press. The one illustrated is home made - but to be honest you can probably buy one ready-made just as cheaply.

Make sure it is large enough to accommodate full sheets of counters. And I'd suggest getting/making a six-screw model to ensure optimum even pressure. Get nice long bolts so you can press multiple sheets at the same time, and wing nuts make it quicker and easier to use.

Leave the counters for a few hours or, ideally, overnight.

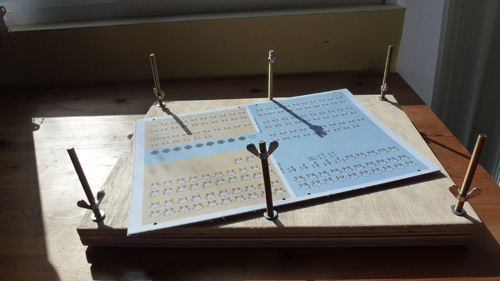

Alignment Jig

If you are intending to make double-sided counters, you'll need some means of ensuring the front and rear are aligned. There are a number of ways of doing this. Personally I use the following jig (based on the recommendation of Karoly Szigetvari) and it appears to work very well - though accuracy during manufacture is critical.

Get a piece of medium thickness (c.5mm) ply or similar and cut slightly larger than A4/Letter size.

- Place the a printout of the template in each of the four corners of the wood, accurately marking the centre of the alignment holes as you do so. You should end up with 8 hole centres marked (2 per template position)

- Drill the holes (accurately and squarely) to a diameter slightly smaller than the die's alignment pin diameter.

- Lightly sand the surface of the wood to ensure it is free from burs around the holes and is clean.

- Screw in screws of the same diameter as the die's alignment pins - these should protrude around 5mm (3mm absolute minimum).

Other Tools & Materials

There are a variety of other tools that will be required or are recommended:

- Hole Punch - this should punch holes the same diameter as your alignment pins. There are (at least) two varieties available, Metal Handheld 1 Hole Punch (Target Price c. £2) (Ensure these are wide enough and deep enough to punch the counter card at the location of the alignment holes) and Screw Hole Punch (Target Price c.£10) (I'm tending to use this as I suspect it is more accurate)

- Rotary Cutter (Target Price c.£35) - not absolutely necessary but certainly helpful.

- 18" Steel Rule (Target Price £3) - I don't actually tend to use this as a rule, but rather use it to 'carefully' lever the counter sheets off the alignment jig (it can - and should be - a tight fit).

- If using an inkjet printer, Fixative Spray (Target Price £10) - again, you don't need this but it will increase the longevity of your finished product. Remember to get Matte, Silk or Gloss - as suits your needs.

- Soft cloth (a gent's cotton hankerchief is fine) - for smoothing down the counter sheets when mounted to the card

- Card stock / grey board (1mm)

- Self-adhesive labels (A4/Letter, 1 per sheet) (Target Price £16 per 100)

- Printer paper - this can be either photo-paper or plain inkjet paper, depending on the finish/effect you're after (and remember the fixative (if used) will also affect the finish).

AND FINALLY

My sincere thanks to John Cooper, Kerry Anderson and Karoly Szigetvari for their help, guidance and counsel.